-

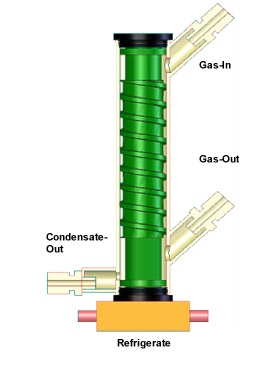

More Efficent and no energy loss even in high ambient temperatures

- Coldness transfer through copper and aluminum,

- Thermal conductance values 300 and 200 W/m°C,

- Coldness transferred from the inside outwards.

-

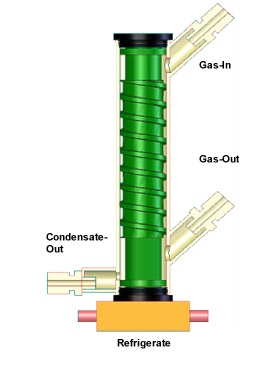

High and constant dryness rate even at extreme load changes

- Hydrophobic surface through coating,

-

large condensate drops are formed immediately,

- sprial performing stream goes downwards,

- discharge of condensate at the lowest point.

-

Low dissolution rate a contribution to more environmental protection

- Very small dead space (26ml),

- extremely short response time of gas to liquid,

- large drops have a similar surface to content ratio,

- PTFE-coating with low electrostatic current,

- condensate spiral stream seperated from 3 sides.

-

Keys to reliability

- Chemical resistance thanks to the PTFE-coating,

- no clogging due to the self cleaning feature.

-

Comprehensive testing procedures guarantee equipment reliability

- Providing of true inlet dew-points,

- automatic control of gas mixture at inlet,

- trace gas measuring by infra-red analyzer,

- data processing and storing,

- availability of test certificates.

|

|